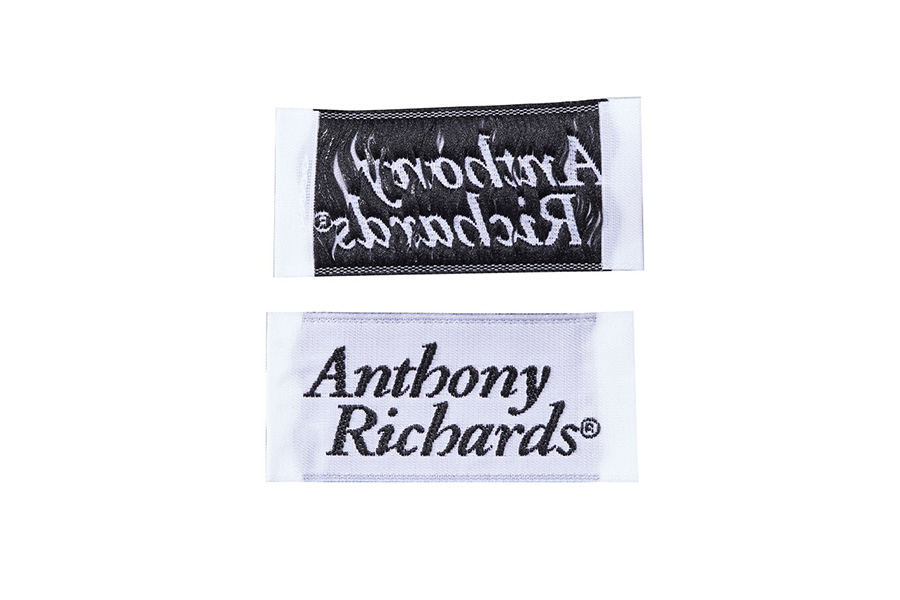

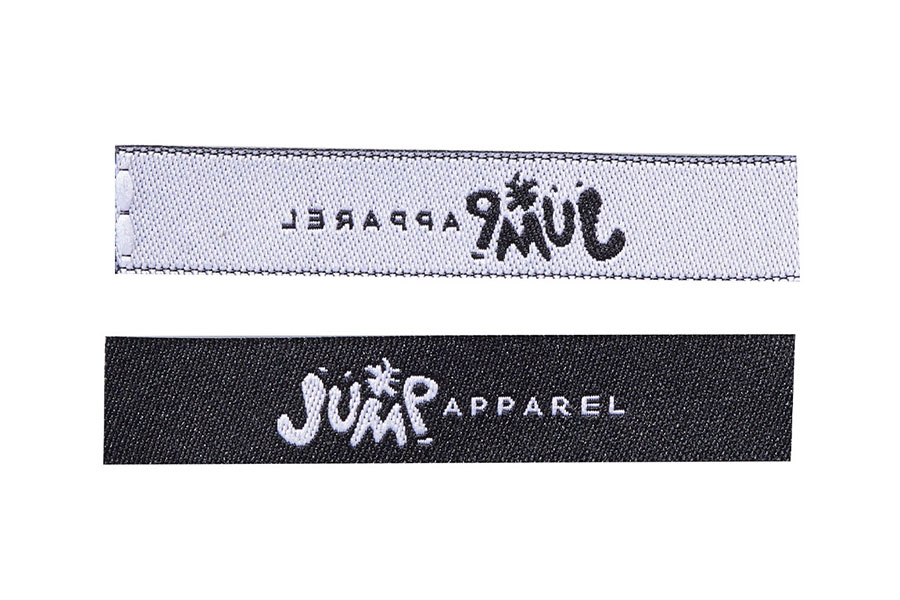

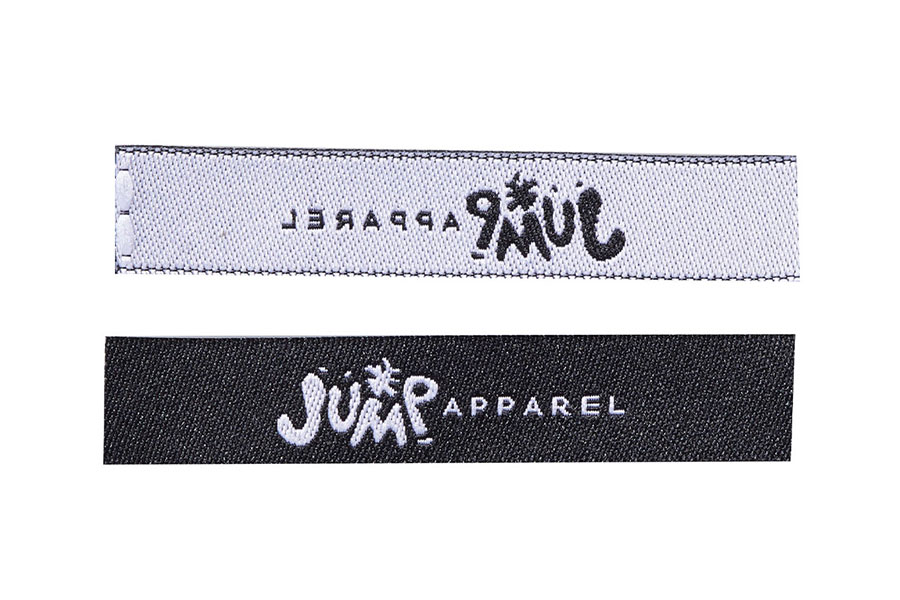

Logo Woven Label

Custom Woven Labels

-

Americas, Europe and Middle East:Phone: 917-891-1278Email: csjsdhangers@gmail.com

-

Asia, except Middle East:Phone: +86-13119695540Email: tsjsdhanger@163.com

Logo woven labels are custom labels that incorporate brand logos, text, or designs directly onto fabric through a weaving process. They are commonly used on clothing, bags, shoes, and hats. Made from textile fibers, they are precision-woven using high-density looms. Different colored yarns are precisely positioned to create brand logos and design details. Compared to printed labels, woven labels offer a softer feel, greater wear resistance, and feature clear, three-dimensional patterns with long-lasting color stability.

Logo Woven Label features

1. High-Density Weaving

The logo woven label utilizes a high-density weave with over 600 stitches per square inch (SSI) for smooth, crisp edges. Yarn diameters range from approximately 75D to 150D, enabling precise image reproduction with an accuracy of less than 0.2mm.

2. Strong Color Durability

Using disperse dyes with a high-temperature color-fixing process, the colorfastness reaches ISO 105-B02 level 5 or higher. Even after over 50 washes and sun exposure, the color remains vibrant and fade-resistant. This stability ensures the clarity and consistency of the brand logo over time.

3. Soft and Comfortable Touch

The woven label is made of polyester or nylon filaments interwoven with a thickness of approximately 0.25mm. After heat setting, it feels smooth and non-rigid. The fibers undergo desizing and a softening finish, reducing the coefficient of friction to below 0.3, ensuring a non-irritating effect against the skin.

4. Precise Pattern Positioning

The equipment utilizes an electronic jacquard control system, achieving pattern positioning accuracy of 0.1mm. Different colored yarns precisely match the color positions of the original design, ensuring consistent proportions between lines and text. Even on small labels, brand details and intricate design elements are clearly visible, ensuring 98% visual fidelity.

5. High Abrasion Resistance and Tensile Strength

The woven label has been tensile tested to achieve a breaking strength of over 40N, capable of withstanding repeated mechanical washing and the strain of sewing. After over 10,000 cycles of friction and abrasion testing, the yarn remained intact and linted. This ensures the label's durability over extended wear and use, preventing edge fraying and unraveling.

1. Apparel Industry

In the apparel industry, logo woven labels are widely used on collars, hems, cuffs, and other locations to display brand and sizing information. Their washable and abrasion-resistant properties ensure that the font and color remain intact even after frequent washing. High-quality woven labels enhance the quality of clothing and brand recognition, giving the product a more professional image in the market.

2. Luggage Manufacturing

In leather goods and luggage, woven labels are often sewn onto the lining or exterior decoration to display brand logos. Their high-density structure resists friction and tearing, making them durable even under frequent use. The three-dimensional effect of woven labels enhances brand recognition and adds a refined look to the luggage.

3. Footwear

Woven labels are often used on the tongue, heel, or insole of shoes, serving both brand display and decorative purposes. Their high-temperature and fade-resistant properties ensure that the pattern remains legible even after prolonged wear and washing. Their flexible structure provides comfortable wear and meets footwear manufacturing standards.

4. Home Textiles

Woven labels are used on home textiles such as bedding, curtains, and towels to identify the brand and material. The soft and washable fabric ensures it remains flat even after home laundering. Heat-sealed edges prevent unraveling, enhancing the overall craftsmanship and brand image of the home textile.

5. Industrial and Custom Apparel

Logo-woven labels are used on workwear, protective clothing, and team uniforms to identify departments, companies, or brands. Their heat-resistant and abrasion-resistant properties make them suitable for various work environments, ensuring clear and legible identification. Customizable colors and fonts allow for standardized corporate identity systems (CIS).

Logo Woven Label maintenance

1. Gentle Cleaning

When washing products containing woven labels, use a neutral detergent and keep the water temperature below 40°C. Avoid using chlorine bleach to prevent damage to the fiber and dye structure, which can cause color fading. Hand washing or using the gentle cycle can effectively extend the life of the label.

2. Avoid High-Temperature Ironing

Woven labels may curl or melt due to high-temperature treatment. We recommend ironing at a temperature not exceeding 110°C. If ironing is required, cover the label with a cotton insulation layer to protect the surface fibers and maintain a smooth pattern.

3. Avoid Exposure to Sunlight

Prolonged exposure to sunlight can degrade the molecular structure of polyester fibers, causing slight yellowing. Drying in the shade or air-drying in a well-ventilated area is recommended to preserve the label's color and softness. Store away from direct light and high temperatures.

4. Regular Inspection

After extended use, regularly inspect the label for loose edges or unraveling. If damaged, repair or replace it promptly. Keeping the label intact not only helps maintain a neat appearance but also prevents seams from affecting the wearer's experience.

5. Proper Storage

Unused woven labels should be stored rolled up in a dry carton, avoiding heavy pressure or folding. The ideal storage humidity is 50% to 60%. A desiccant can be added to prevent moisture absorption and deformation of the yarn. Proper storage ensures that the label remains flat and its color remains stable when it is reused.

Taishan Jinshunda Garment Accessories Products Co., Ltd. was founded in 2001, and for nearly a quarter of a century it has focused on manufacturing premium plastic products while sustaining a stellar reputation in the industry.

Company headquarters are located in Taishan City within the Guangdong Province in China. Its modern and spacious facilities, covering almost 141,000 square feet, are equipped with advanced, production equipment and proficient technical staff. Both are crucial to ensure the development of first-rate plastic goods that include clothes hangers, elastic and disposable food containers. Plastic clothes hangers feature innovative design combined with reliable sturdiness. These hangers not only meet demanding daily usage requirements, they are also aesthetically appealing and can support a full range of garments. In addition, elastic is pliable and can withstand a high level of wear and tear.

Plastic food containers are constructed of high-grade and environmentally friendly materials that offer superior sealing performance. Therefore, whether containers are used for meal storage or carrying take-out, food placed within these durable containers remains fresh and do not leak.

Due to the relentless pursuit of creating top-quality merchandise that meets customers’ wide-ranging needs, our plastic products have sold extensively in both domestic and international markets. They have successfully garnered the trust of our clients and we will undoubtedly continue to strive for innovation, excellence and service of the utmost level.