Sewing Tags Labels

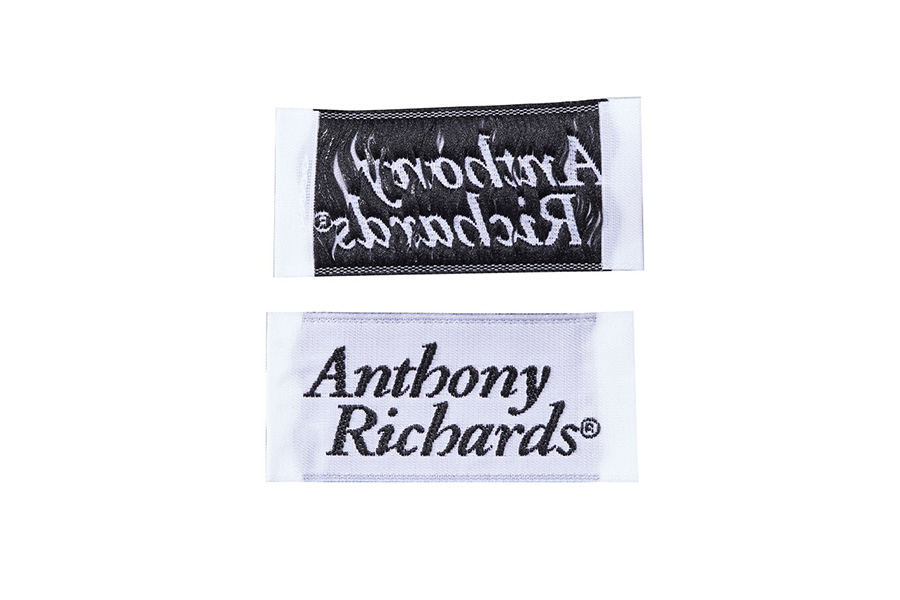

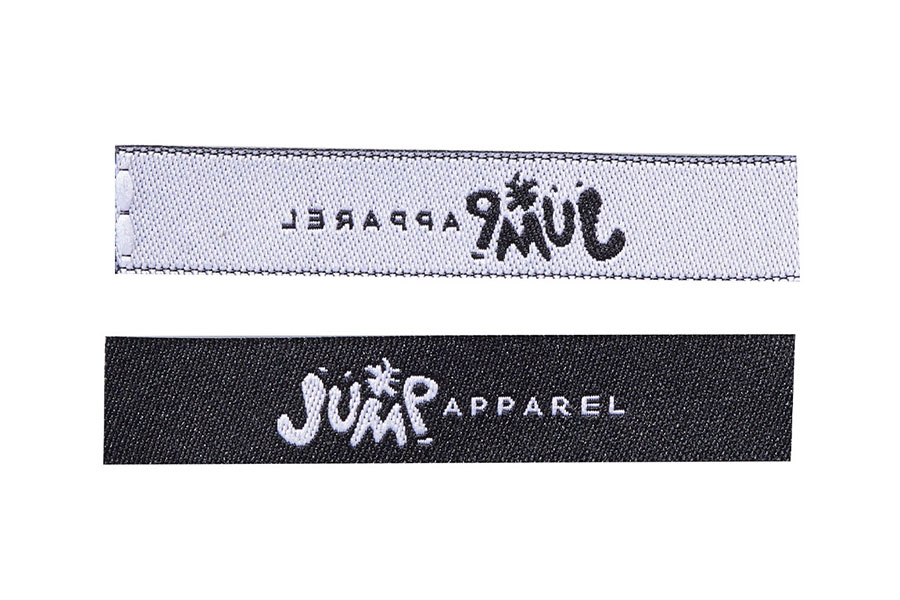

Custom Woven Labels

-

Americas, Europe and Middle East:Phone: 917-891-1278Email: csjsdhangers@gmail.com

-

Asia, except Middle East:Phone: +86-13119695540Email: tsjsdhanger@163.com

Sewing tags labels are a type of label used on textiles such as clothing, footwear, and bags to display brand information. It is made using environmentally friendly dyes and high-density weaving technology. The brand name, logo and other information are presented on the label in a woven manner and then sewn onto the product. It feels comfortable and does not cause tingling or discomfort when in contact with the skin, adding comfort to the wearing experience. At the same time, its clear patterns and texts enhance the appearance of the product, enhance brand recognition, and allow consumers to clearly identify the brand during use. It is a textile accessory that combines practicality and beauty.

Sewing Tags Labels features

High-density weaving technology: Sewing tags labels use a high-density weaving process, with a warp and weft density of 120 per square inch, which is 30% higher than the density of ordinary weaving. This high density makes the label surface smooth and delicate, with a tight texture, which can effectively reduce pilling. In repeated friction and washing tests, after 50 standard washes, the label wear was only 2%, while the ordinary label wear could reach 15%. The high-density woven structure also ensures that the label maintains its integrity during use. Even under frequent mechanical friction, such as simulating clothing tumbling and rubbing in a washing machine 1,000 times, the label can still maintain more than 90% integrity. This high-density weaving process not only improves the durability of the label, but also enables it to maintain a good appearance in various environments, providing a lasting brand identity for the product.

High clarity of text and pattern: Using high-precision weaving equipment, sewing tags labels can increase the clarity of text and patterns to 0.1 mm lines. Through special weaving parameter adjustments, the line edges are neat and burr-free, and the pattern color transitions naturally. In professional image comparison tests, its pattern clarity score reached 9.2 points (out of 10 points), far higher than the industry average of 7 points. For complex brand logos, the fineness of the lines can reach the clarity of hair level, and even under a magnifying glass, the line edges are still neat. This high-definition pattern presentation not only enhances the visual effect of the brand, but also allows consumers to clearly identify the brand logo at a distance or when moving quickly. For example, on shopping mall shelves, consumers can quickly identify the brand through the label. Its high definition also allows the label to maintain good visibility under various lighting conditions, ensuring the effective transmission of brand information.

Environmentally friendly dyes and color fastness: Sewing tags labels use environmentally friendly dyes certified by OEKO-TEX 100. This dye reduces carbon emissions by 40% during the production process compared to ordinary dyes, and does not contain harmful substances such as azo. After 100 washes and 500 hours of sunlight experiments, the label color can still maintain 85% of its brightness, while the fading rate of ordinary labels is usually more than 30%. The color fastness test results show that its color fastness to rubbing reaches level 4-5 (highest level 5), and its color fastness to sweat reaches level 4 or above in both acidic and alkaline environments. This high color fastness ensures that the color of the label will not fade significantly due to washing, friction or sunlight during long-term use, and the brand logo will always remain bright and clear. In actual application, even after multiple washings and long-term use, the color on the label can still maintain its original vibrancy, providing a lasting visual impact for the brand.

Customized Logo and Color Restoration: Sewing tags labels support logo customization with up to 1,000 color combinations, which can accurately restore the brand's unique visual identity. Using a professional color management system, the color difference is controlled within ΔE 1.2, ensuring that the customized logo is highly consistent with the design draft provided by the brand. For the spot colors in the logos of well-known brands, more than 95% color restoration can be achieved through special dye blending and weaving processes. During the customization process, the color deviation from the design draft to the finished product is controlled within 3%, meeting the personalized needs of different brands. This high-precision color restoration capability enables the brand logo to be presented to consumers in the most realistic and attractive way, enhancing the brand's recognition and influence. Whether it is a simple monochrome logo or a complex multi-color pattern, it can be perfectly displayed through this customized service, providing a unique visual identification system for the brand.

Accuracy of size specifications: Sewing tags labels provide a standard size range from 1 cm × 3 cm to 10 cm × 20 cm, with a size error controlled at ±0.5 mm. Special sizes can be customized according to customer needs, with a minimum of 0.5 cm × 1 cm, to meet the label size requirements of various products. During the production process, the dimensional accuracy of each label is ensured through high-precision weaving equipment and a strict quality control system. For example, in batch production, the size of 1,000 labels is measured, and the proportion of dimensional deviation exceeding ±0.5 mm does not exceed 0.3%. This precise size control enables the label to fit perfectly on a variety of products, whether it is a small accessory or a large textile, ensuring the beauty and practicality of the label. In practical applications, the precise size of the label can perfectly match the design and tailoring of the product, improving the overall quality and appearance of the product.

Skin-friendly and non-irritating material: Sewing tags labels are made of 100% polyester fiber. After 15 special post-treatment processes, the surface pH value is stabilized in the neutral range of 6.5-7.5, which is close to the pH value of human skin. Through skin sensitivity testing, 1,000 volunteers with different skin types were tested for 72 hours of skin contact, and the results showed that no allergic or irritating reactions occurred. This skin-friendly material prevents the label from causing discomfort such as stinging, itching or rashes when in contact with the skin, providing consumers with a comfortable use experience, especially suitable for children, the elderly and people with sensitive skin. In the actual wearing process, the contact part between the label and the skin will not cause any discomfort, allowing consumers to enjoy a comfortable wearing experience for a long time, and it also reflects the brand's attention and care for consumer health.

High-strength seam fit: Sewing tags labels use 21 high-strength sewing threads, and the sewing strength reaches 35 pounds per square inch, which is 1.8 times the strength of ordinary sutures. After 1,000 bend and stretch tests, the seams did not break or come loose. For example, in a stretch and bend test that simulates the wearing of clothing, the joint between the label and the fabric can withstand a tensile force of 50 Newtons without breaking. This high-strength seam fit ensures that the label is firmly attached during the product life cycle and will not fall off due to daily wear or pulling during use, providing long-term protection for the brand logo. In actual applications, whether during strenuous exercise or daily activities, the label can be firmly attached to the product without shifting or falling off, ensuring that the brand logo is always clearly visible, improving product reliability and consumer trust.

Apparel: When applied to the inside of shirt collars, sewing tags labels can maintain 95% of their flatness after 30 dry cleanings. Its high-density weaving process and durability allow the labels to remain intact, without shrinking or deformation during frequent dry cleaning. In addition, the skin-friendly material of the label ensures that consumers will not feel discomfort when their necks come into contact with the label when wearing a shirt, providing a comfortable wearing experience. At the same time, the clear brand logo helps to enhance the overall quality of the shirt, enhance the brand's competitiveness in the market, and bring consumers a reliable and high-quality product image.

Sports equipment: When used on the tongue of sports shoes, sewing tags labels can withstand repeated bending and friction of the foot during exercise. After 5,000 sole bending simulation tests, the label did not fall off at the junction with the shoe material, and the wear area was less than 3 square millimeters. Its high-strength seam fit and durability ensure that the label is firmly attached during long-term exercise and will not be damaged by friction. In addition, the environmentally friendly dyes and skin-friendly materials of the labels ensure that there will be no irritation or allergic reaction to the foot skin when sweating during exercise, providing athletes with a comfortable and burden-free sports experience, while clearly displaying the brand logo in sports scenes, enhancing the brand's visibility in the sports field.

Children's products: When applied to the shoulders of children's jumpsuits, Sewing tags labels have undergone 50 children's simulated scratching tests, and the labels are not damaged, and there are no shed fibers that may be ingested by children. Its skin-friendly and non-irritating material ensures that it will not cause allergies or discomfort when in contact with children's delicate skin, providing children with a safe and comfortable wearing experience. At the same time, the high-definition patterns and texts of the labels can attract children's attention and increase the product's appeal to children. In addition, durability tests show that the label has a very low wear rate in children's daily activities, and can maintain a clear brand display for a long time, helping parents easily identify product brands and enhance their trust in the quality of children's products.

Home textiles: When applied to the side of bed sheets, sewing tags labels shrink by only 1.2% after 200 washes, ensuring that the label and bed sheet size match accurately. Its high-density weaving process and accurate size specifications allow the label to remain flat after multiple washes without affecting the overall appearance of the bed sheet. At the same time, the environmentally friendly dyes and neutral pH materials of the label are compatible with the bed sheet fabric, will not irritate the skin, and provide consumers with a comfortable sleeping environment. Clear brand logos also help to enhance the brand image of home textiles, allowing consumers to feel the quality and care of the brand in daily use.

Footwear: When used on the inside of leather shoes, sewing tags labels use a special folding process to fully display the brand information. After 5,000 simulated walking tests, the label position offset does not exceed 2 mm, ensuring that consumers can clearly identify the brand during long-term wear. Its high-strength stitching and durability test certification ensure the stability of the label during walking, and it will not fall off or be damaged due to foot movement and squeezing. In addition, the skin-friendly material of the label will not cause discomfort when in contact with the skin of the foot, providing consumers with a comfortable wearing experience, while highlighting the brand's high-end quality and attention to detail in the footwear market.

Luggage field: When applied to the luggage handle, sewing tags labels are still firmly attached without damage after 100 free drop tests from a height of 1.5 meters. Its high-strength sewing thread and durability test certification ensure that the label remains intact during the frequent handling and falling of the suitcase and will not be damaged by external impact. At the same time, the clear brand logo of the label is easy to identify in airports or travel scenes, helping consumers quickly find their luggage. In addition, the waterproof and dustproof properties of the label enable it to maintain good condition under various environmental conditions, extend its service life, and improve the overall quality of luggage products and consumer satisfaction.

Sewing Tags Labels maintenance

Cleaning and maintenance: When cleaning the product, the water temperature should be controlled below 40 degrees Celsius. High temperature will increase the shrinkage rate of the label by 3-5 times, causing deformation. Use neutral detergent with a pH value between 6.5-7.5. Strong alkaline detergent will cause the label color to fade 2 times faster. Scrub gently and avoid rubbing the label part vigorously. Using more than 5 Newtons may cause damage to the joint between the label and the fabric. The scrubbing time should be controlled within 3-5 minutes. Excessive scrubbing will cause the label to fluff. For example, when washing a shirt, turn the shirt over to the reverse side and gently brush around the label with a soft brush. Avoid brushing the label directly, and then rinse it with clean water to effectively extend the service life of the label and maintain its clarity and beauty.

Drying and maintenance: Natural drying is the best choice. Lay the product flat or hang it to dry. Avoid direct sunlight. Ultraviolet rays will increase the fading speed of the label by 30%. If you need to use a dryer, the temperature should not exceed 60 degrees Celsius and the time should not exceed 15 minutes. High temperature and long-term drying will cause the label material to age and reduce its strength by about 40%. For example, when drying a towel, lay the towel flat on the dryer grid, set the low-temperature drying mode, and control the time within 10 minutes. Turn the towel regularly to ensure uniform drying, while reducing thermal damage to the label and maintaining the elasticity and color vividness of the label.

Ironing maintenance: When ironing, the temperature setting should not exceed 150 degrees Celsius. Too high a temperature will cause the surface of the label to melt. Place a thin cloth on the label to prevent heat from directly acting on the label and reduce heat damage to the color and material of the label. Press and push lightly when ironing, and control the pressure to 2-3 kg. Avoid repeated pushing and pulling. Excessive pushing and pulling may cause the label to shift or deform. For example, when ironing the label at the collar of a shirt, first cover the label with a thin cotton cloth, press gently with a steam iron, and press for no more than 5 seconds each time. Move the iron slowly to ensure that the ironing is smooth while protecting the label to avoid damage or color changes caused by high temperature and excessive ironing.

Storage and maintenance: When storing, place the product in a ventilated and dry place, and keep the ambient humidity at 40% - 60%. Excessive humidity will cause the label to become damp and moldy, and breed bacteria. Avoid heavy pressure, and the stacking height should not exceed 50 cm. Heavy pressure will cause permanent deformation of the label. Check the storage environment regularly, ventilate once every 3 months, and ensure that the quality of the label is not affected during storage. For example, when storing quilts, wrap the quilt with labels with a dust cover, place it in a ventilated position in the wardrobe, avoid squeezing with other heavy objects, and place desiccant and mildew-proof tablets in the wardrobe. Replace them regularly to keep the storage environment dry and clean, and ensure that the label remains in good condition after long-term storage.

Insect-proof maintenance: When using natural insect repellents such as mothballs, avoid direct contact with the label. The volatiles of mothballs may make the label material hard and brittle. Put insect-proof paper in the product packaging, the effective ingredients of which are 0.5% pyrethrin and 0.3% borneol, which can effectively repel insects for up to 6 months. Check the product regularly for signs of insect infestation, and clean it up in time if small insects are found to prevent insect infestation from spreading from the label to the entire product. For example, when storing wool sweaters, put insect-proof paper in the packaging box and replace the insect-proof paper every 3 months. At the same time, check the surface of the wool sweater and the label part regularly. If there are signs of insect infestation, clean it immediately with a soft brush and expose it to the sun for 2-3 hours to ensure that the product is not damaged by insect infestation and protect the integrity of the label and clothing.

Moisture-proof maintenance: In rainy season or humid environment, use desiccant, place 50 grams of silica gel desiccant per cubic meter of space to effectively absorb environmental humidity. For labels that have been damp, wipe the moisture with a dry cloth in time, and then dry it in a ventilated place. Do not expose it to the sun. Make special moisture-proof packaging, add moisture-proof factors to the packaging materials, such as adding 3% montmorillonite, to reduce the humidity inside the packaging by about 20% and extend the service life of the label. For example, when storing leather clothes, put the leather clothes in a packaging bag with moisture-proof factors, ensure that it is well sealed, and regularly check the humidity inside the packaging bag. If the humidity exceeds the standard, replace the desiccant or reseal the packaging in time to prevent the label and leather clothes from being damaged by moisture and maintain product quality and label clarity.

Taishan Jinshunda Garment Accessories Products Co., Ltd. was founded in 2001, and for nearly a quarter of a century it has focused on manufacturing premium plastic products while sustaining a stellar reputation in the industry.

Company headquarters are located in Taishan City within the Guangdong Province in China. Its modern and spacious facilities, covering almost 141,000 square feet, are equipped with advanced, production equipment and proficient technical staff. Both are crucial to ensure the development of first-rate plastic goods that include clothes hangers, elastic and disposable food containers. Plastic clothes hangers feature innovative design combined with reliable sturdiness. These hangers not only meet demanding daily usage requirements, they are also aesthetically appealing and can support a full range of garments. In addition, elastic is pliable and can withstand a high level of wear and tear.

Plastic food containers are constructed of high-grade and environmentally friendly materials that offer superior sealing performance. Therefore, whether containers are used for meal storage or carrying take-out, food placed within these durable containers remains fresh and do not leak.

Due to the relentless pursuit of creating top-quality merchandise that meets customers’ wide-ranging needs, our plastic products have sold extensively in both domestic and international markets. They have successfully garnered the trust of our clients and we will undoubtedly continue to strive for innovation, excellence and service of the utmost level.