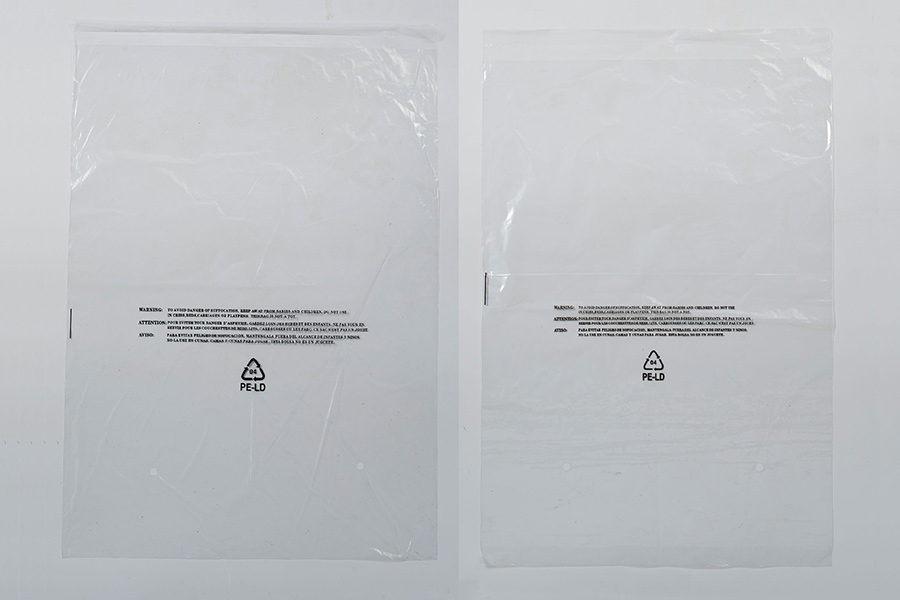

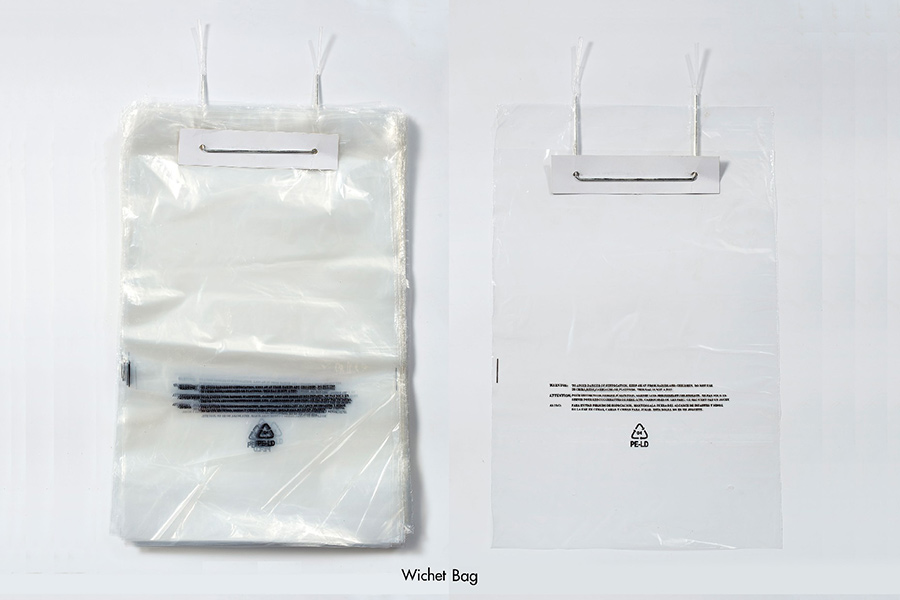

Garment Wicket Bags

Garment Packaging Bags

-

Americas, Europe and Middle East:Phone: 917-891-1278Email: csjsdhangers@gmail.com

-

Asia, except Middle East:Phone: +86-13119695540Email: tsjsdhanger@163.com

Wicket bags are a type of stacked plastic packaging bag specifically designed for clothing and garment packaging processes. They are secured by hooks, allowing for continuous bag dispensing. In practical use, the bags unfold smoothly and maintain a stable direction, resulting in a natural and continuous garment packaging process. This makes them suitable for high-frequency packaging environments and helps improve the consistency and efficiency of clothing packaging operations.

Garment Wicket Bags Features

1. Stable Bag Dispensing

Wicket bags utilize a double-hole structure and metal hooks, allowing for a single bag dispensing time of 0.8–1.2 seconds. In continuous dispensing tests, the bag opening offset rate is less than 2%, helping to maintain a stable operating rhythm and reduce the frequency of manual adjustments.

2. Consistent Specifications

The entire stack of wicket bags is produced using a uniform mold, with bag width and length dimensions controlled within a tolerance of ±1.5mm. Under a 1000-bag sampling test, the consistency pass rate reaches 98%, facilitating subsequent automatic or semi-automatic packaging processes.

3. Bag Opening Positioning

The bag opening punch position and distance from the edge remain stable, with a hole position deviation controlled within ±0.8mm. This design maintains consistent bag opening direction during high-speed dispensing, reducing the probability of bag rotation or folding and improving packaging efficiency.

4. Reliable Load-Bearing Capacity

Wicket bags commonly use PE material with a thickness range of 20–60μm. In standard tests, a single bag can carry 2–5kg of contents without rupture. The bag body has even stress distribution, suitable for the basic packaging needs of various product types.

5. Neat Stacking

The number of bags in each stack can be controlled between 100–250, with a stacking height error of less than 3%. This feature facilitates warehousing and workstation management, keeping the dispensing area clear and organized, and reducing space waste in the packaging area.

1. Garment Factory Packaging

At the end of the garment production line, wicket bags provide a continuous supply of bags, allowing a single person to bag approximately 800-1200 garments per hour. The consistent bag orientation reduces the time spent flipping and organizing bags, making it suitable for packaging standard garments such as T-shirts and shirts.

2. E-commerce Warehouse Shipping

E-commerce order packaging emphasizes speed and neatness. Wicket bags allow for smooth bag retrieval at fixed workstations, with the bag opening remaining stable. In scenarios with thousands of orders per day, this helps maintain the packaging pace and reduces manual fatigue and operational errors.

3. Branded Clothing Inner Packaging

As inner packaging bags for branded clothing, wicket bags maintain the flatness of the garments and reduce wrinkles. The consistent bag size facilitates subsequent boxing and display management, suitable for brand orders that require consistent appearance.

4. Garment Sorting Center

In sorting environments with multiple styles and sizes, wicket bags allow for quick and efficient sorting and packaging. The fixed hole spacing design ensures neat bag arrangement, reducing bag mix-ups and improving sorting accuracy and overall operational efficiency.

5. Export of Garments

Garment exports typically require batch bagging and verification. Wicket bags are easy to count and manage in stacked form. The stable bag specifications help standardize packaging before export, facilitating boxing and inventory processes.

Garment Wicket Bags FAQs

Q: Can wicket bags only be used manually?

A: Wicket bags can be used manually or with semi-automatic equipment. As long as the hook size matches, stable bag dispensing can be achieved without affecting the dispensing rhythm.

Q: How does different thickness affect usage?

A: Thickness mainly affects load-bearing capacity and feel. Thinner specifications are suitable for lightweight products, while thicker specifications are more stable when loading heavier items. The appropriate thickness can be selected based on the weight of the contents.

Q: Do the bags stick together during use?

A: Through reasonable formulation and production control, the electrostatic attraction between the bags can be reduced to a controllable range. Under normal conditions, the probability of bags sticking together is low.

Q: Is it possible to customize the size and printing?

A: Wicket bags support customization of bag length, width, and hole spacing. Simple printing can also be added as needed to meet branding or information labeling requirements.

Q: How is the stacked form maintained during transportation?

A: Finished products are usually transported using flattening and external packaging for fixation, ensuring good stacking stability. Under normal logistics conditions, scattering or deformation problems are unlikely to occur.

Taishan Jinshunda Garment Accessories Products Co., Ltd. was founded in 2001, and for nearly a quarter of a century it has focused on manufacturing premium plastic products while sustaining a stellar reputation in the industry.

Company headquarters are located in Taishan City within the Guangdong Province in China. Its modern and spacious facilities, covering almost 141,000 square feet, are equipped with advanced, production equipment and proficient technical staff. Both are crucial to ensure the development of first-rate plastic goods that include clothes hangers, elastic and disposable food containers. Plastic clothes hangers feature innovative design combined with reliable sturdiness. These hangers not only meet demanding daily usage requirements, they are also aesthetically appealing and can support a full range of garments. In addition, elastic is pliable and can withstand a high level of wear and tear.

Plastic food containers are constructed of high-grade and environmentally friendly materials that offer superior sealing performance. Therefore, whether containers are used for meal storage or carrying take-out, food placed within these durable containers remains fresh and do not leak.

Due to the relentless pursuit of creating top-quality merchandise that meets customers’ wide-ranging needs, our plastic products have sold extensively in both domestic and international markets. They have successfully garnered the trust of our clients and we will undoubtedly continue to strive for innovation, excellence and service of the utmost level.