How To Make Pant Hangers

Pant hangers may look simple, but behind every sturdy and elegant design lies a precise manufacturing process that combines material science, mechanical engineering, and product aesthetics. From raw material selection to injection molding, from automatic hook insertion to final quality control, every stage defines how a pant hanger performs — its grip, durability, and longevity.

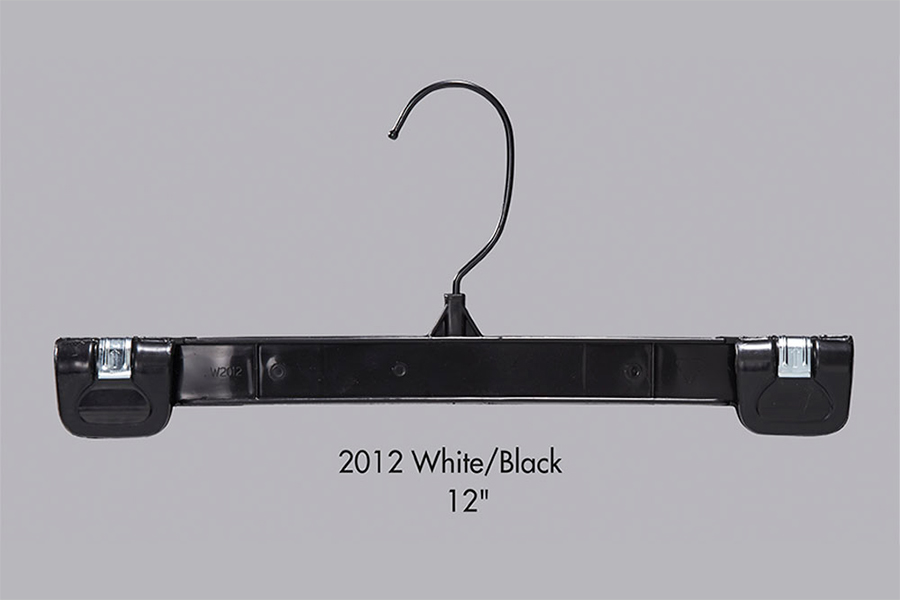

At Jinshunda, we specialize in producing high-quality Bottom Hangers for both retail and household use. This article explores how pant hangers are made, what technologies ensure their consistency, and how design improvements elevate them beyond simple storage tools.

1. Selecting the Right Raw Materials

The creation of pant hangers begins with the selection of premium plastic resins. The most common materials used are polypropylene (PP) and ABS plastic, both known for their toughness, elasticity, and environmental safety. The right plastic type directly influences hanger weight, flexibility, and surface texture.

Before entering the production line, plastic pellets are carefully inspected for purity, density, and color consistency. Impurities can weaken molecular bonding during the melting process, leading to brittle hangers or surface imperfections. At Jinshunda, every batch of raw material is certified for non-toxicity and high temperature resistance, ensuring each hanger meets international export standards.

In addition, eco-friendly additives are introduced during the blending process. These improve UV resistance, anti-aging properties, and smoothness — extending the lifespan of the hangers while reducing environmental impact. The goal is to achieve a perfect balance between strength and sustainability, reflecting Jinshunda’s commitment to responsible manufacturing.

2. Injection Molding — Shaping Precision and Strength

Injection molding is the core process in hanger production:contentReference[oaicite:0]{index=0}. Plastic pellets are precisely fed into a high-performance injection molding machine, where they are heated to a molten state at temperatures between 200°C and 280°C. Under immense pressure, this liquid plastic is rapidly injected into custom steel molds designed to replicate the exact form of a pant hanger.

Key Steps in the Molding Process:

Melting and Pressure Injection — The raw plastic is melted uniformly to achieve smooth flow into every cavity of the mold.

Cooling and Solidification — Once injected, the molten plastic cools and solidifies within seconds, capturing every design detail, from bar grooves to anti-slip ridges.

Ejection and Trimming — When cooled, the hanger is automatically ejected from the mold, and excess material (called flash) is trimmed away.

High-end molds are essential for achieving precision. Jinshunda’s molds are crafted with micrometer accuracy, ensuring consistent dimensions and clean surfaces. The combination of automated temperature control and high-pressure systems guarantees hangers that are sturdy, perfectly aligned, and ready for industrial-scale production.

3. Automatic Hook Insertion — The Strength Behind the Grip

After the main body of the hanger is molded and inspected, it enters the automatic hook insertion stage, a key process that combines mechanical accuracy with structural reliability:contentReference[oaicite:1]{index=1}.

Pre-Insertion Preparation

Before hooks are installed, technicians calibrate the automated insertion machine according to the specific hanger model. Stainless steel hooks, known for their high tensile strength and corrosion resistance, are arranged neatly in the feed channel. Each hook undergoes tension testing to ensure it can withstand long-term use without deformation.

Intelligent Insertion Process

The hanger is positioned precisely by an automated clamp, while sensors ensure alignment accuracy. The machine’s insertion arm then drives each hook into the pre-molded socket at high speed, with tolerances measured in micrometers. The process completes in milliseconds — achieving perfect verticality and secure attachment every time.

Quality Verification

Once hooks are inserted, each hanger passes through an online inspection station. Systems check insertion depth, rotation angle, and grip stability. Any defective product triggers an automatic rejection alert. This ensures that every Jinshunda pant hanger delivered to clients meets high standards for stability, symmetry, and performance.

4. Anti-Slip Function — Engineering That Holds

Pant hangers are not only about holding garments; they must prevent slippage without damaging the fabric. The anti-slip function is one of the defining aspects of a premium hanger.

Surface Texture and Design

During the molding stage, subtle textured ridges or rubber-coated bars are added to increase friction. These prevent pants from sliding off, even when the material is smooth or heavy. Jinshunda’s bottom hangers often feature dual-grip clips with soft PVC pads that hold fabric securely yet gently.

Clip Mechanism

The clips undergo a separate molding process and are attached during assembly. Precision steel springs provide balanced tension, ensuring grip strength remains constant after thousands of uses. Each clip is lined with anti-scratch pads, so trousers stay wrinkle-free and unmarked.

Functional Coating

For specialized hangers used in humid environments or retail displays, a silicone or flocking finish is applied. This creates a soft-touch feel and a higher coefficient of friction, offering reliable performance while enhancing the hanger’s aesthetic appeal.

Through these engineering innovations, Jinshunda ensures that every hanger provides a strong yet fabric-friendly hold — combining safety with function in every detail.

5. Assembly, Testing, and Quality Control

After molding and hook installation, hangers move into final assembly and testing. This stage is crucial for ensuring that every hanger leaving the production line meets the brand’s quality promise:contentReference[oaicite:2]{index=2}.

Assembly

If the hanger design includes additional components — such as multi-layer clips, plastic connectors, or swivel heads — they are installed using semi-automatic machines. Workers perform alignment checks to verify that all joints move smoothly and maintain consistent pressure.

Comprehensive Testing

Each hanger type undergoes a set of standardized durability tests, including:

Load-bearing test: Measures the maximum weight a hanger can hold without deformation.

Spring resilience test: Ensures the clip’s elasticity remains intact after repeated use.

Surface inspection: Detects bubbles, warping, or flash from molding.

Hook rotation test: Confirms the metal hook maintains 360° rotation without loosening.

Quality Assurance

Only hangers that pass all tests are approved for packaging. Jinshunda’s automated inspection systems minimize human error, maintaining consistency even at high output levels. This rigorous quality process ensures that every pant hanger performs flawlessly, from the production floor to the customer’s wardrobe.

6. Packaging and Global Distribution

Once hangers are fully inspected, they move to the packaging line. This final step is more than simple wrapping — it’s a process that protects, organizes, and brands the product for export:contentReference[oaicite:3]{index=3}.

Eco-Friendly Packaging

Jinshunda uses recyclable cardboard boxes and protective wraps to reduce environmental impact while ensuring durability during transport. Each box is clearly labeled with product specifications, quantity, and brand logo for easy warehouse identification.

Efficient Logistics

The hangers are counted, bundled, and stacked in uniform rows before being sealed. Palletized shipping ensures efficient handling and stable loading during international transport. As a global supplier, Jinshunda’s logistics system supports bulk OEM and ODM orders, with strict adherence to export standards and delivery timelines.

Market Adaptation

Different markets prefer different hanger designs — Europe favors minimalist matte finishes, while Asia often prefers bright, functional styles. Jinshunda’s flexible production model allows customized colors, branding, and surface treatments, helping global partners build consistent retail presentations.

Conclusion

The process of making pant hangers is a combination of precision engineering and craftsmanship. From the selection of high-grade plastics to injection molding, from automatic hook assembly to strict quality control, every step reflects an unyielding pursuit of reliability and performance.

At Jinshunda, we take pride in producing bottom hangers that merge technology with practicality. Our automated production lines and expert team ensure each hanger not only looks polished but also withstands daily use in homes, laundries, and clothing stores worldwide.