How To Make Plastic Hangers Non-Slip?

Slipping clothes are rarely caused by the fabric alone. In most closets, retail backrooms, garment factories, and laundries, the real reason is the contact surface between the hanger and the garment. Smooth plastic shoulders plus lightweight fabrics, wide necklines, or angled shoulder seams can easily slide. A non-slip plastic hanger solves this by increasing friction, improving garment positioning, and keeping weight distribution stable so the garment stays where it was placed.

This article explains the proven, manufacturer-grade ways to make plastic hangers non-slip, what each method is best for, and how Jinshunda designs adult and child plastic hangers to reduce slipping in real daily use. If you need to review styles and size options, please browse our adult plastic hangers and child hangers.

I. Why Plastic Hangers Slip and What Non-Slip Really Means

A plastic hanger becomes slippery when the surface is too smooth for the garment fabric, or when the hanger geometry does not match the garment structure. Low-friction contact is only part of the story. The shoulder angle, shoulder width, and any stabilizing points like notches, bars, or clips also determine whether the garment stays centered.

In practical operations, slipping tends to happen in four scenarios:

Lightweight fabrics with low surface friction

Satin, rayon, silk-like blends, thin knits, and many synthetics can slide even on mildly textured surfaces.Garments with wide necklines or open shoulders

Camisoles, off-shoulder tops, wide-neck T-shirts, and many children’s clothes have less structure to anchor on the hanger.Mismatch between hanger width and garment size

A hanger that is too wide pushes fabric outward and changes shoulder seam alignment. A hanger that is too narrow concentrates weight and encourages the garment to fall inward.High-movement environments

Retail racks, sorting lines, delivery routes, and high-frequency pick-and-place handling increase the chance of garments sliding off.

Non-slip is therefore not one single feature. A good non-slip plastic hanger combines surface friction and structural support so garments remain stable during hanging, moving, and repeated use.

II. The Most Reliable Non-Slip Solutions Used in Plastic Hangers

There are several proven approaches to preventing slippage. The best results usually come from choosing the right solution for the garment type rather than applying one universal method to everything.

A. Shoulder notches and strap hooks for secure positioning

Notches are one of the simplest and most effective tools for preventing slipping on straps and wide necklines. They work by creating a mechanical stop point rather than relying only on friction. This is especially useful for camisoles, lingerie items, and many children’s garments where strap position changes easily during handling.

For buyers, notch geometry matters. A notch that is too shallow will not hold. A notch that is too sharp can snag delicate straps. Manufacturer-controlled molding and consistent notch definition help keep strap retention stable across bulk orders.

B. Textured shoulder surfaces to increase friction without extra materials

Texturing can be engineered directly into the plastic surface, increasing friction while keeping the hanger easy to clean and lightweight. This approach is common in high-turnover environments where hangers are frequently wiped down or exposed to lint.

Textured surfaces are also practical for mixed garment racks where buyers want a general non-slip improvement without adding coatings. The key is consistency. Uneven texture can create weak areas where fabrics slide, or create roughness that catches delicate materials.

C. Anti-slip grooves, bars, and clips for pants and two-piece sets

For pants, a smooth bar can cause sliding and creasing. Pants-specific hangers often use anti-slip grooves or clip-style structures to hold fabric flat and stable. In our product range, plastic pants hangers are designed with anti-slip groove or clip structures to help keep trousers smooth and reduce wrinkling during storage and display.

This is not only a convenience feature. In retail and factory environments, stable hanging reduces rework time, improves display consistency, and supports faster sorting.

D. Wider shoulder designs to prevent garment deformation and slippage

Wider shoulders reduce pressure points and better match garments with structured shoulder seams. This reduces slipping because the garment sits naturally, instead of balancing on a narrow contact edge.

Suit hangers are a clear example. A widened shoulder area follows the suit shoulder line and helps prevent deformation while also supporting stability. Jinshunda offers suit hangers with widened shoulders designed to fit suit shoulder lines and maintain shape during hanging. When the garment is supported properly, it is less likely to slide.

E. One-piece set hangers to keep outfits together without shifting

Two-piece outfits often slip because the top and bottom are hung separately and shift relative to each other during movement. Integrated set hangers solve this by holding multiple garment components together.

Our product introduction includes integrated hangers designed to hang tops and pants together, keeping outfit combinations complete and helping maintain organized racks. In practice, this also reduces slipping because the garments are positioned with intentional anchor points rather than hanging loosely.

III. Choosing the Right Non-Slip Method by Garment Type

Different garments slip for different reasons. The most cost-effective solution is to match the hanger structure and surface to the product category being handled.

Below is a practical reference that buyers often use when planning hanger specifications.

| Garment Type | Most Common Slip Cause | Recommended Non-Slip Approach | What to Prioritize |

|---|---|---|---|

| Camisoles and strap tops | Straps shift and slide | Shoulder notches, strap hooks | Notch shape consistency, smooth edges |

| Lightweight blouses and knitwear | Low friction surface | Textured shoulders, gentle friction surfaces | Balanced texture, no snagging |

| Trousers and slacks | Bar sliding, folding, creasing | Grooved bar, clip structure | Even holding force, flat hang |

| Suits and jackets | Shoulder collapse, shifting on narrow shoulders | Wide shoulder suit hangers | Shoulder contour, load stability |

| Children’s clothing | Small size mismatch, wide necklines | Correct width Child Hangers, notches | Right sizing, stable shoulder angle |

| Sets and coordinated outfits | Garments shift relative to each other | Integrated set hangers | Multi-point support, space efficiency |

Jinshunda’s hanger lineup covers multiple styles including standard plastic hangers, pants hangers, underwear hangers, set hangers, suit hangers, and integrated hangers. This category breadth is important for non-slip performance, because different garments require different holding structures rather than one generic hanger shape.

IV. Why Correct Sizing Is a Non-Slip Feature, Not Just a Dimension

Many slipping complaints come from using the wrong hanger size. Even the best anti-slip surface cannot fully compensate for width mismatch.

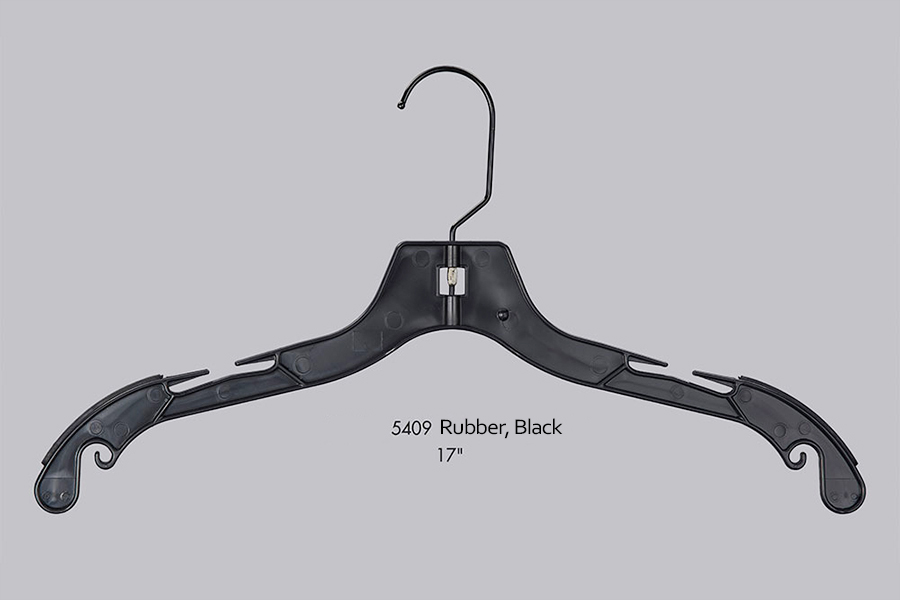

Our product introduction defines a clear size span: plastic hangers range from 8 inches to 19 inches, with 8 to 10 inches for child plastic hangers and 15 to 19 inches for adult hangers. This sizing distinction is not only for fit. It directly impacts how stable a garment sits.

A properly sized hanger supports the garment’s shoulder seam and balances its center of gravity. This reduces fabric creep and prevents garments from migrating toward the neck opening. For children’s clothing, correct sizing is especially critical because necklines and shoulder seams are often softer and more flexible. When the hanger is too wide, a child’s garment can slip off even if the surface is textured.

For adult garments, width selection helps with both stability and shape retention. A suit hanger that matches shoulder width can reduce shifting and maintain garment form, which is one of the reasons wider-shoulder suit hangers are widely preferred for structured apparel.

V. How Jinshunda Builds Non-Slip Performance Into Plastic Hangers

Non-slip outcomes depend on repeatability. In bulk purchasing, buyers do not only want one hanger that works. They want every carton to perform the same way across long-term use. That requires process control.

A. Injection molding stability supports consistent surface and geometry

Jinshunda’s manufacturing process includes injection molding where selected plastic pellets are melted and injected under pressure into precision molds, then cooled and formed into the hanger body. For non-slip features like notches, grooves, and textured surfaces, injection molding consistency is crucial because small variations can change how well the garment is held.

When mold cavities are controlled and cooling is stable, structural details such as groove definition and shoulder line remain consistent. This improves garment stability and reduces performance variability across batches.

B. Quality inspection reduces defects that cause slipping

After molding, each hanger undergoes quality inspection to check appearance defects such as flashing, bubbles, or deformation, and to measure size accuracy. For non-slip performance, deformation matters more than it may appear. A slightly warped shoulder or uneven bar angle can make garments slide even if the surface is designed for friction.

Consistent inspection helps ensure that hangers intended to hold garments securely do not enter packing with geometry drift.

C. Automatic hook insertion improves stability and long-term handling reliability

Hook stability affects non-slip indirectly. A loose hook can tilt the hanger, shifting the garment’s center of gravity and increasing slip risk. The process includes an automatic hook insertion stage where the hanger is positioned, the metal hook is inserted with precision, and the hook’s firmness and insertion depth are checked in an online inspection station.

This matters in commercial environments where hangers are moved frequently. A stable hook helps keep the hanger level, which supports consistent garment placement and reduces sliding.

D. Protective packaging supports finish quality during shipping and storage

Packaging also affects non-slip performance. If surfaces are scratched or deformed during transit, friction behavior changes. The process uses protective packaging materials and cartons with clear identification for logistics handling. This reduces the chance that hanger surfaces and edges are damaged before use.

VI. Practical Ways Buyers Use Non-Slip Plastic Hangers in Real Operations

In many commercial settings, hangers are not just storage tools. They are part of operational efficiency and brand presentation. The product introduction highlights that hangers support efficiency and image in commercial operations and are suited for malls, stores, garment factories, and laundries.

Non-slip benefits show up in measurable ways:

Faster display maintenance

Garments that stay in place reduce the need for rehanging and repositioning.Lower loss from dropped garments

Less slipping means fewer garments falling to the floor, reducing handling damage and cleaning rework.Better presentation consistency

When garments hang evenly, racks look more organized and product silhouettes display more accurately.Improved sorting and processing speed

In factories and laundries, stable hanging reduces interruption during movement and batching.

These outcomes are why professional buyers often treat non-slip features as part of cost control, not only as a premium add-on.

VII. Selecting the Right Jinshunda Hanger Styles for Non-Slip Needs

Instead of trying to force one hanger style to cover everything, a more reliable approach is to build a small, purposeful set of hanger types that match your garment categories.

A practical, low-complexity specification structure often includes:

Standard plastic hangers for general tops and daily apparel

Pants hangers with groove or clip structures for trousers and slacks

Suit hangers with widened shoulders for structured garments

Integrated or set hangers for coordinated outfits to keep combinations stable

Correct-width child hangers aligned with child sizes, especially for softer garments

If you want to review the available styles and match them to your garment categories, please browse our adult plastic hangers and child hangers.

Conclusion

Making plastic hangers non-slip is not about one quick trick. It is about combining friction control and structural support: shoulder notches for straps, engineered texture for everyday fabrics, groove or clip structures for pants, widened shoulders for suits, and correctly sized hangers that match garment dimensions. When these elements are built consistently through injection molding, inspected for deformation, fitted with stable hooks through automated insertion, and protected through shipping, non-slip performance becomes repeatable at scale.

Jinshunda offers a broad plastic hanger range from 8 to 19 inches, covering child and adult categories, and multiple hanger styles designed for different garment handling needs. If you need to learn more about product options and select the right styles for stable, non-slip hanging, please browse our adult plastic hangers and child hangers.