Do Plastic Hangers Snap in Cold Weather?

Yes, plastic hangers can snap in cold weather, but it does not happen to every hanger and it is not only about temperature. Snapping is usually the result of three factors working together: the plastic formulation, the hanger structure, and the way the hanger is handled in a low-temperature environment. When plastic is exposed to cold, many polymers become less flexible and absorb less impact energy. If the hanger is thin at high-stress points, overloaded with heavy garments, twisted during fast handling, or dropped onto a hard floor, cracking becomes more likely.

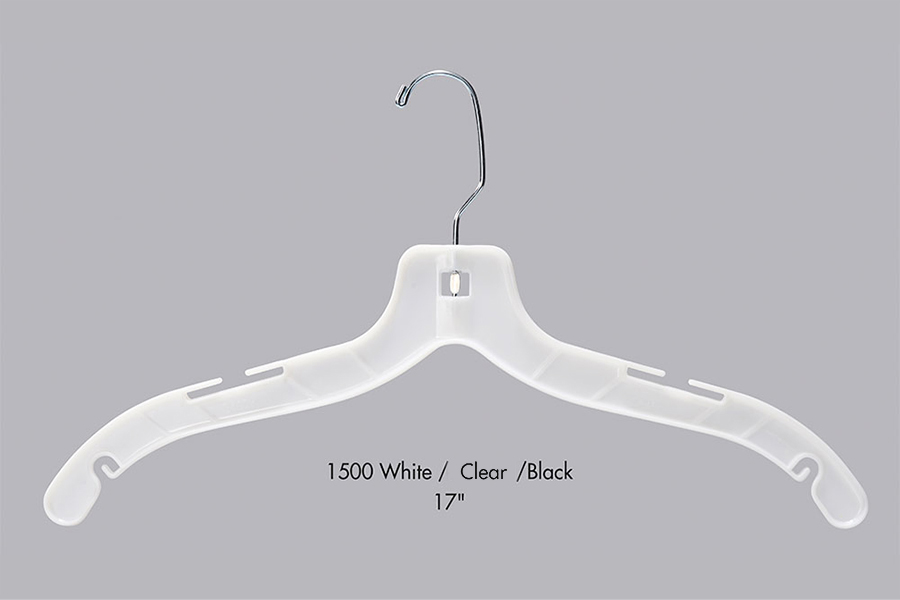

This article explains why cold weather can make plastic hangers brittle, what situations create the highest break risk, and how Jinshunda designs adult and child plastic hangers to improve reliability for everyday closets and commercial operations. If you need to learn more about product styles and sizes, please browse our adult plastic hangers and child hangers.

I. What Actually Causes a Plastic Hanger to Snap in Cold Weather

Cold does not usually break a hanger on its own. The break typically happens at the moment of stress, such as twisting the hook, pulling a tight neckline over the shoulder, knocking hangers off a rack, or hanging heavy winter garments that create a concentrated load.

In low temperatures, many plastics shift from a more flexible behavior to a more rigid behavior. When a material becomes rigid, it can still hold weight, but it becomes less forgiving to sudden impact or bending. That is why a hanger may feel fine when holding a light shirt but can crack when it is bent sharply or dropped.

Snapping risk rises when:

The hanger is handled outdoors, in unheated warehouses, or during cold-season logistics

Garments are heavier, such as coats and padded jackets

Handling is fast and repetitive, such as retail replenishment or laundry sorting

The hanger design has sharp corners or very thin sections at stress points

A reliable hanger for cold seasons is one that keeps strength and toughness balanced, and keeps stress distribution stable in the areas where users naturally apply force.

II. Where Breaks Usually Happen on Plastic Hangers

Most hanger failures occur in predictable zones because those zones receive the highest bending forces.

Hook connection zone

This area experiences twisting when hangers are rotated on racks, moved between rails, or pulled off a tightly packed line.Shoulder corners

The shoulder corners can crack when users pull garments over the hanger aggressively, especially thick collars and stiff fabrics. Corner geometry matters because sharp transitions concentrate stress.Thin arms and narrow profiles

Slim hangers are space-saving but can be more vulnerable when overloaded with heavy garments or when the hanger is cold and less flexible.Trouser bar or clip structures

If a pants bar is forced open or bent under load, a brittle plastic can crack, especially if the bar is thin or the motion is repeated.

This is why the best approach is not simply to make a hanger thicker everywhere. It is to reinforce the stress zones, maintain stable geometry, and match hanger type to garment weight and use frequency.

III. Cold-Weather Handling Scenarios That Increase Snap Risk

Many buyers focus on material, but real-world use conditions are often the deciding factor. Cold-weather snapping frequently appears in these scenarios:

Outdoor transport and cold logistics

When hangers are stored in trucks, containers, or temporary outdoor staging areas, the product can cool down significantly. If the hanger is then used immediately and bent or twisted while cold, the chance of cracking increases.

Heavy winter garments and concentrated load

Thick coats, cotton-padded jackets, and heavy outerwear create sustained load on the shoulders. Jinshunda’s product introduction describes suit hangers designed with widened shoulders and strong structure, suitable for hanging heavier winter garments while maintaining shape and resisting deformation. This kind of structural support reduces stress concentration, which is a key contributor to cracking.

High-frequency commercial handling

In malls, stores, garment factories, and laundries, hangers are handled quickly and repeatedly. Jinshunda positions hangers as not only hanging tools but also efficiency and presentation tools for commercial operations. In these environments, stability at the hook and stress points becomes especially important because handling creates repeated micro-stress that can turn into visible cracks over time.

Tight rack density and forced removal

When hangers are packed too closely on a rod, users often twist or pull sideways to remove one garment. That sideways torque acts directly on the hook zone and shoulder corners, which are the most common break areas.

IV. How Jinshunda Builds Durability That Helps in Cold Conditions

Cold-weather snapping is a performance question, so buyers should look at repeatability and process control, not only a single sample test. Jinshunda’s manufacturing workflow focuses on consistent molding quality, accurate assembly, and inspection steps that reduce weak points.

Stable injection molding for consistent structure

The production process uses injection molding where plastic pellets are melted and injected under pressure into a designed mold cavity, then cooled and demolded into the hanger body. For durability, consistency here matters because poor fill, uneven cooling, or warpage can create internal stress and weak edges that crack more easily in cold conditions.

Inspection to reduce warpage and defects that become crack starters

Each hanger is checked for common molding defects such as flashing, bubbles, and deformation, and size is measured before moving forward. In practical terms, deformation is not only a cosmetic issue. A slightly warped shoulder can shift load unevenly, and uneven load makes brittle fracture more likely under cold handling.

Hook insertion that supports stable hanging and reduces twist damage

Jinshunda uses an automatic hook insertion process that positions the hanger accurately and inserts the metal hook with controlled speed and precision, then checks hook firmness, insertion depth, and verticality at an online inspection station. A stable hook reduces wobble and uneven torque in daily use, which helps prevent stress concentration at the hook connection zone.

Protective packaging that helps keep edges and surfaces intact

Packaging uses protective materials and cartons for transport identification and protection. This matters because impacts during shipping can create micro-cracks at corners. Those micro-cracks may not be obvious until the hanger is used in colder conditions, where brittle behavior makes cracks propagate faster.

V. Why Correct Hanger Type and Size Reduce Cold-Season Breakage

A cold-weather break often starts with a mismatch: the wrong hanger style or size for the garment category. When a hanger fits the garment correctly, the garment weight is distributed more evenly and the hanger is less likely to be bent in unnatural ways.

Jinshunda’s range covers plastic hanger sizes from 8 inches to 19 inches, with 8 to 10 inches for Child Hangers and 15 to 19 inches for adult hangers. This size separation is not only about presentation. It also reduces forced stretching of children’s necklines over adult-width shoulders and reduces concentrated load points caused by misfit.

Style selection matters in the same way. Jinshunda offers multiple categories including standard plastic hangers, pants hangers, underwear hangers, set hangers, suit hangers, and integrated hangers. For cold seasons, using a suit hanger with widened shoulders for heavy outerwear is often more reliable than using a thin standard hanger, because the structure is designed to support heavier garments and maintain shape.

VI. Practical Ways to Reduce Snapping Risk Without Changing Your Workflow

Many buyers want solutions that do not require changing staff habits or storage processes. The most practical approach is to make the hanger system more forgiving under cold handling.

Use heavier-duty hangers for heavy garments

Assign suit hangers with widened shoulders to coats and structured jackets to reduce stress concentration.Avoid twisting cold hangers immediately after cold storage

If hangers were stored in unheated areas, letting them warm slightly before high-torque use reduces brittle fracture risk.Reduce rack density in cold-season operations

Leaving a little more space on rods lowers the need to twist and pull sideways, reducing stress at the hook and shoulders.Match child garments to child hanger widths

Child hangers in the correct width range reduce forced bending during garment loading and unloading.Use pants hangers designed for trousers instead of forcing trousers onto standard shoulders

Pants hangers are designed for trousers and help avoid bending hanger arms under load, supporting neat storage and reducing unnecessary stress.

These steps focus on reducing stress events that cause snapping, which is more effective than relying on a single material assumption.

VII. What Buyers Can Expect From Jinshunda Plastic Hangers in Cold Seasons

Cold weather is a stress test for consistency. Buyers generally want three outcomes: fewer broken hangers, stable garment presentation, and smoother operations when seasonal garments become heavier.

Jinshunda supports these outcomes through:

A product range that covers adult and child sizing with clear width separation

Multiple hanger categories designed around garment structure and load types

Injection molding, inspection, and controlled hook insertion that reduce defect-driven weak points

A positioning that serves both household and commercial environments where efficiency and image matter

If you need to learn more about available designs, sizes, and category options, please browse our adult plastic hangers and child hangers.

Conclusion

Plastic hangers can snap in cold weather, but the root cause is usually brittle behavior combined with real-world stress events such as twisting, impact, overload, and misfit. The most reliable way to reduce cold-season breakage is to use a hanger structure that supports the garment correctly, reduces stress concentration at critical zones, and maintains consistent build quality across batches. Jinshunda’s injection molding process, defect inspection, and automated hook insertion with online checks are designed to reduce weak points and improve repeatability. Combined with clear adult and child size ranges and specialized hanger types, this helps buyers run more stable operations in colder seasons.

If you need to learn more about product options and select the right hangers for seasonal garments, please browse our adult plastic hangers and child hangers.